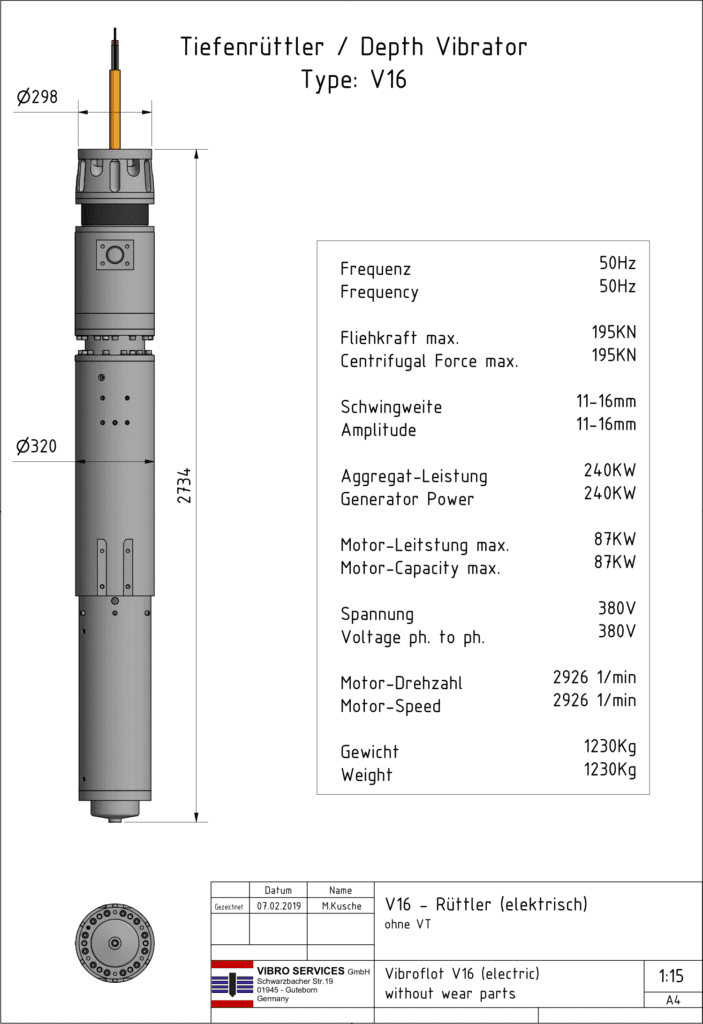

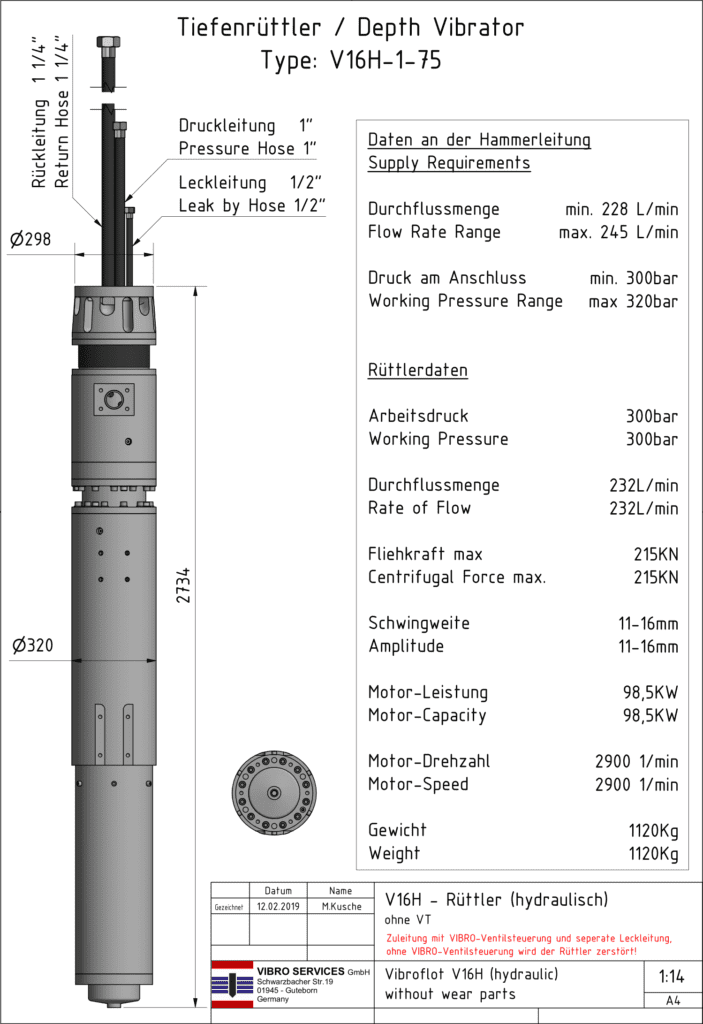

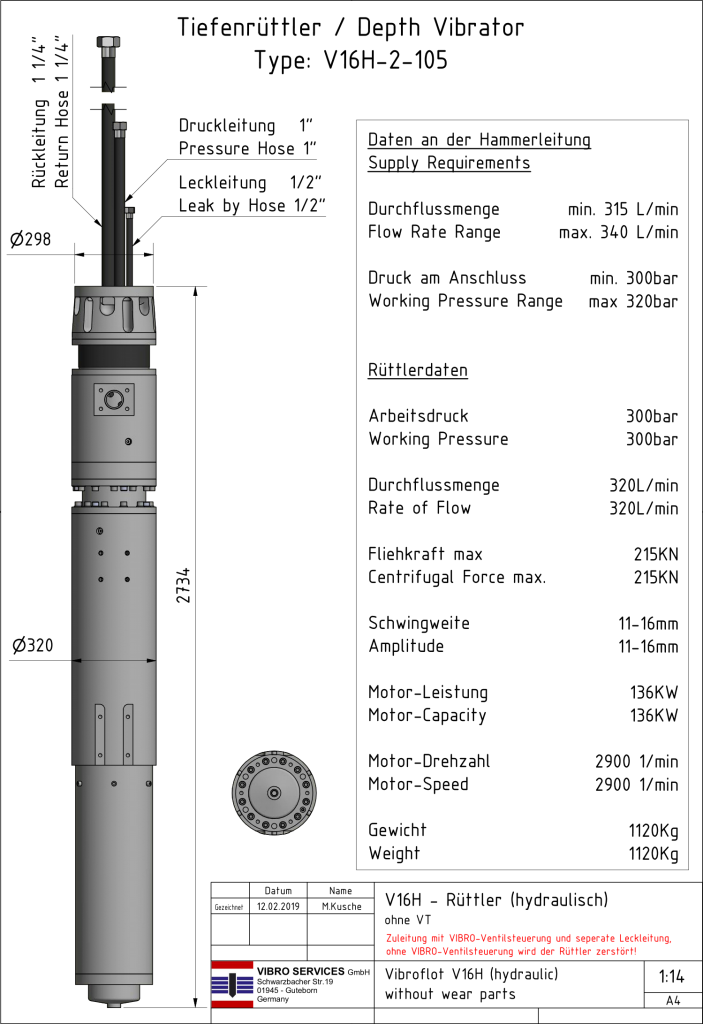

V-16

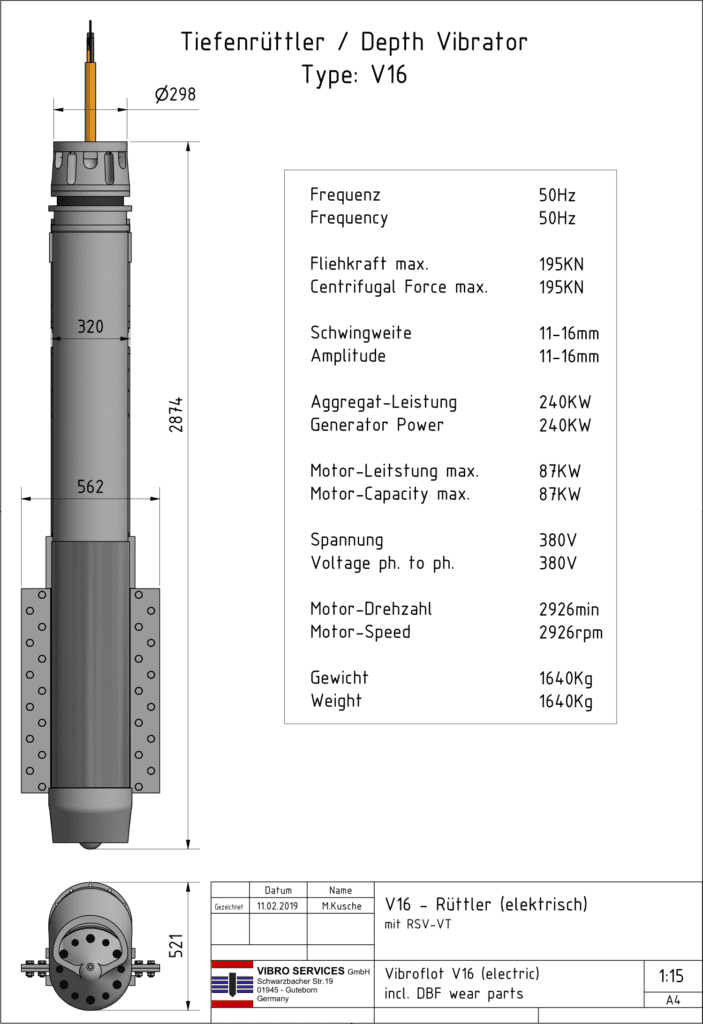

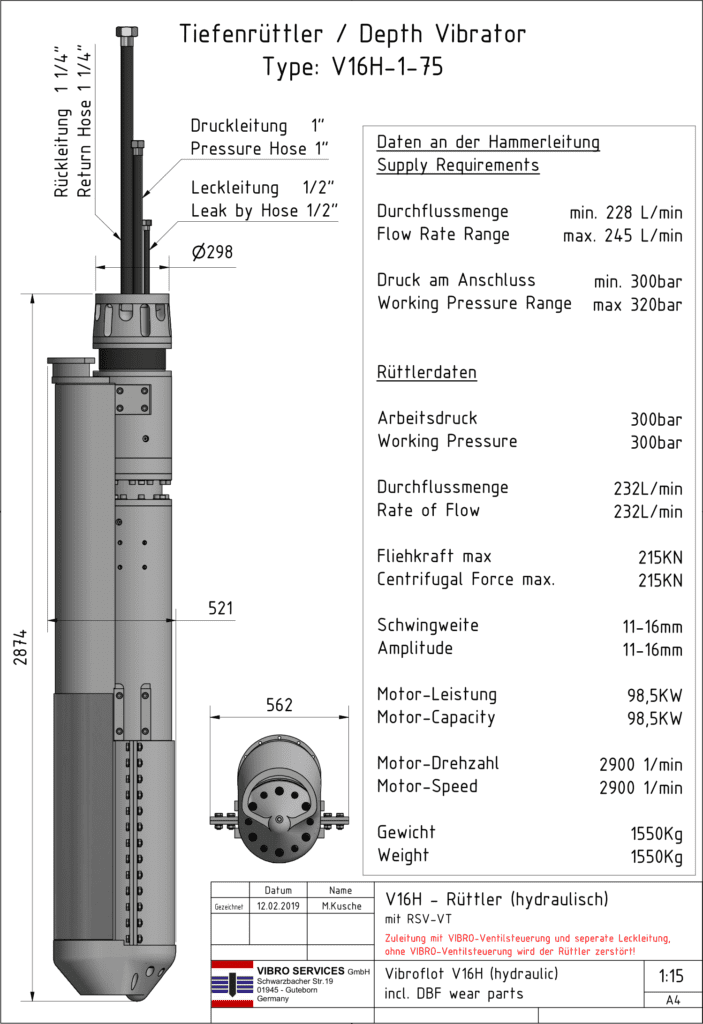

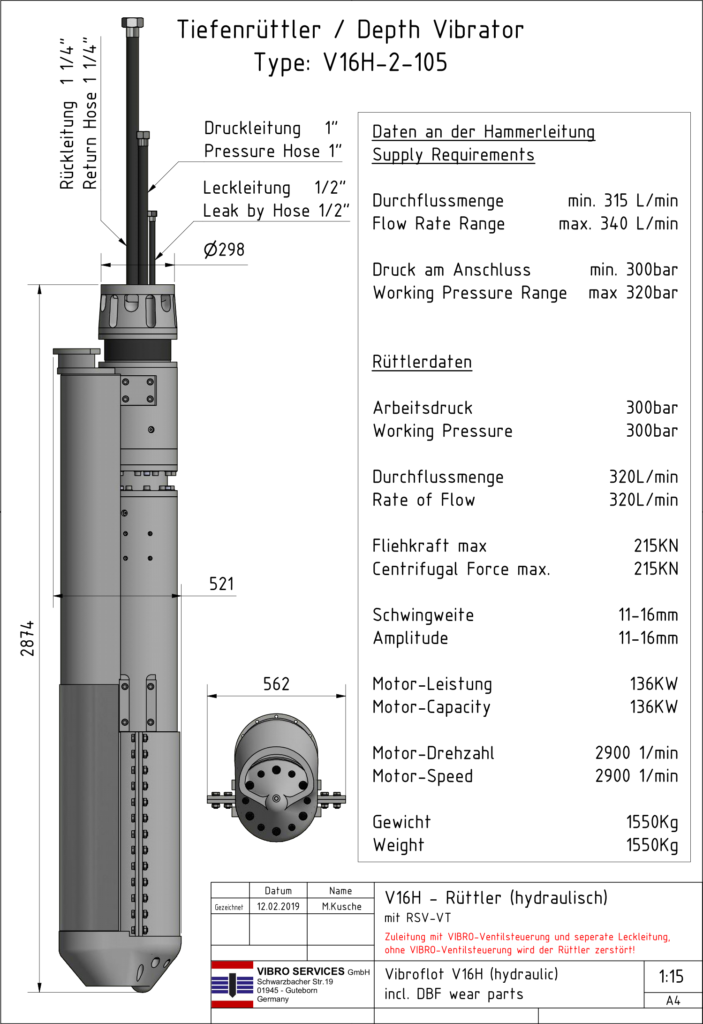

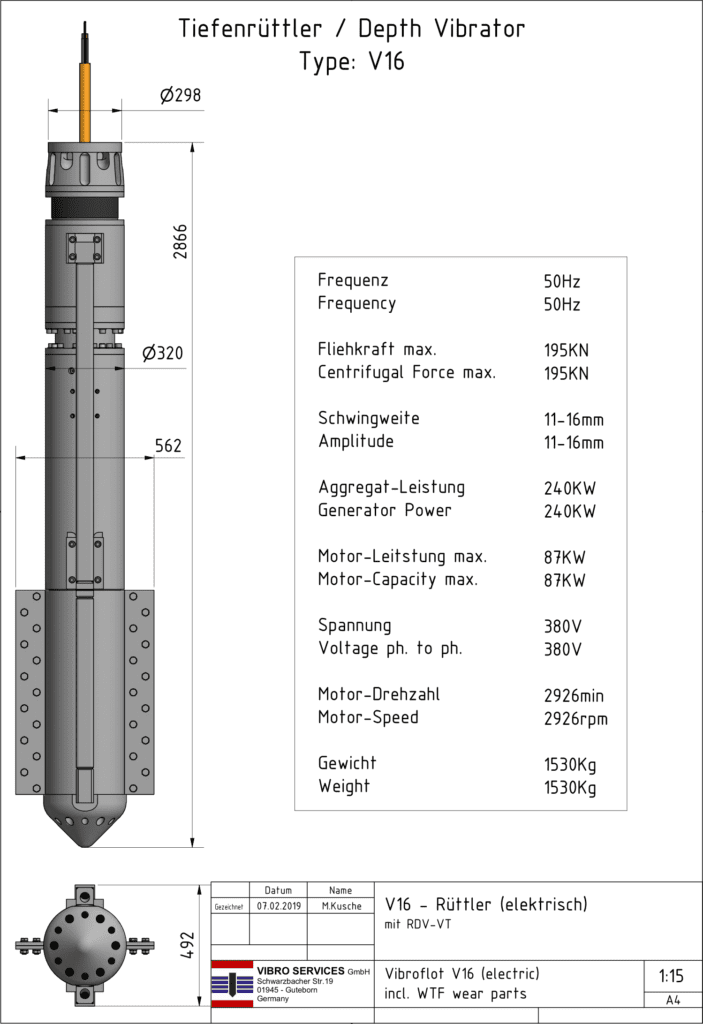

The V-16 is the smallest vibrolot in our portfolio. Currently the V-16 is the only vibroflot with electric and hydraulic drive.

In the sketches below you can see the basic dimensions of the vibroflots as well as the technical data . In addition, the two motor variants of the hydraulically driven vibroflots.

ELECTRICALLY DRIVEN

WITHOUT WEAR PARTS

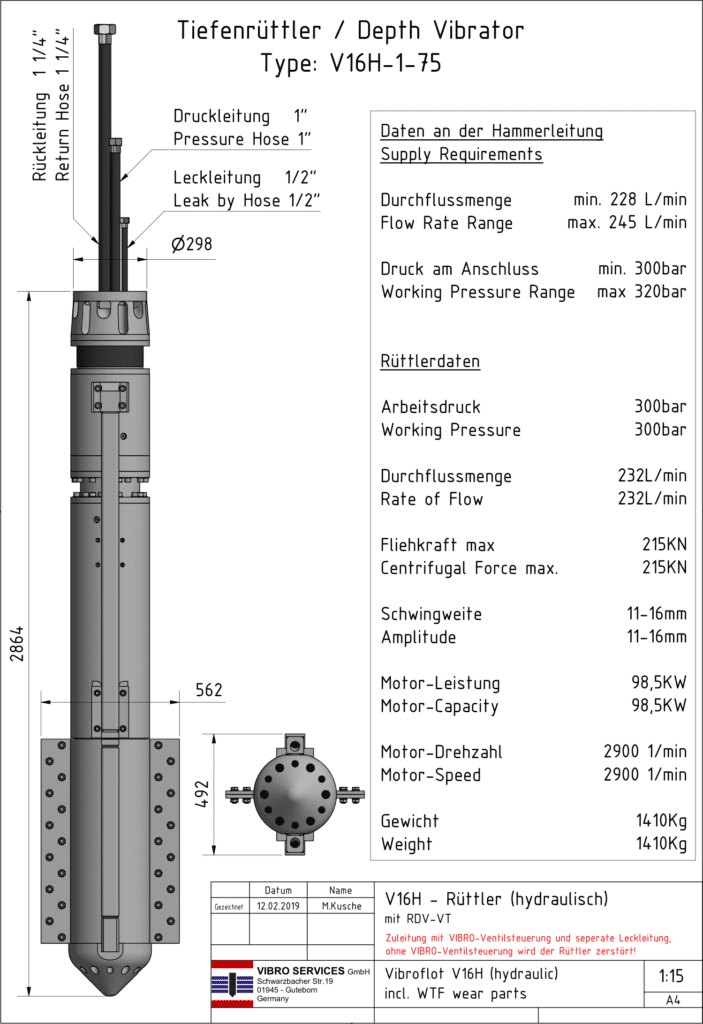

HYDRAULICALLY DRIVEN

WITHOUT WEAR PARTS

Data sheets for the variant with wear parts for the dry bottom feed system (DBF).

ELECTRICALLY DRIVEN

WITH DBF WEAR PARTS

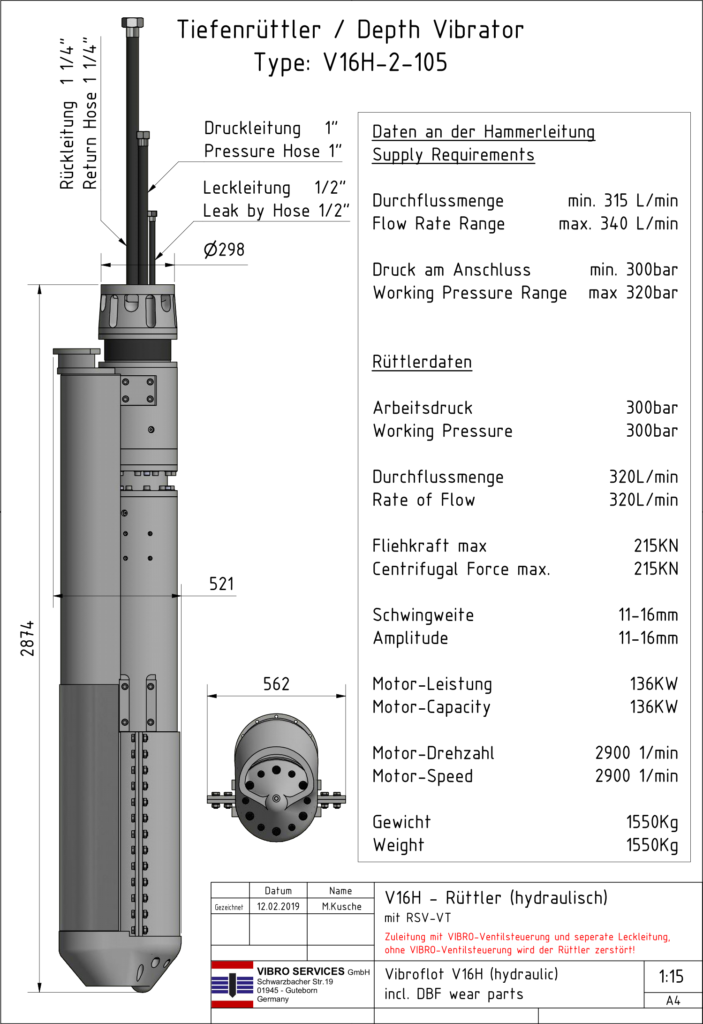

HYDRAULICALLY DRIVEN

WITH DBF WEAR PARTS

Data sheets for the variant with wear parts for vibrocompaction (VC).

ELECTRICALLY DRIVEN

WITH VC WEAR PARTS

HYDRAULICALLY DRIVEN

WITH VC WEAR PARTS

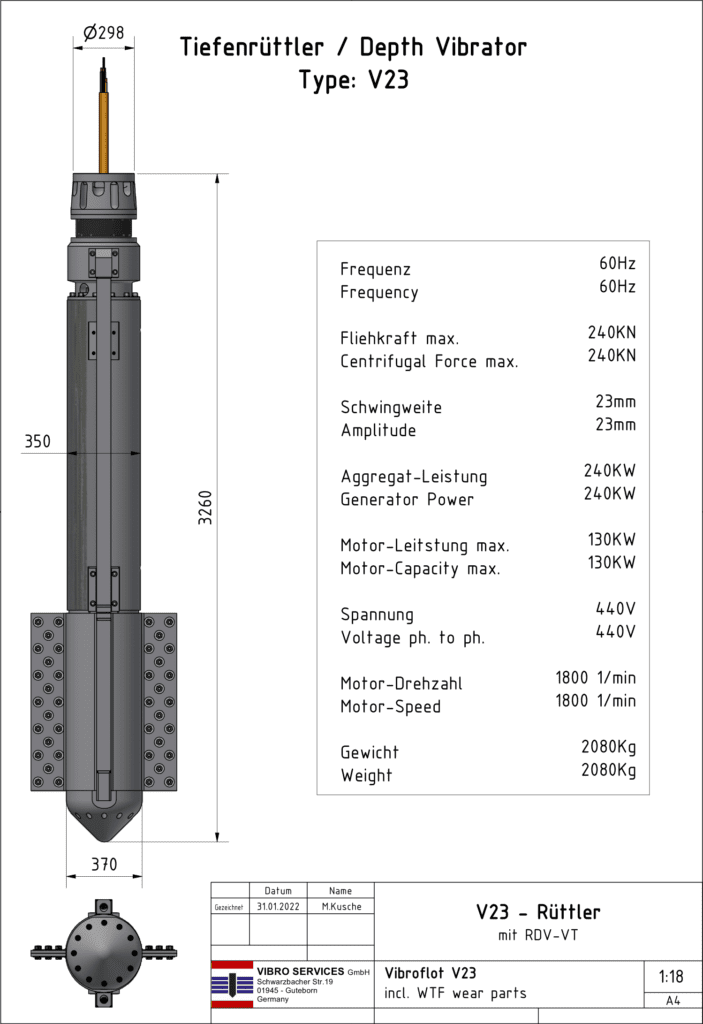

V-23

The V-23 is the mid-range model of the vibrators in terms of power, weight and size. It can be used universally and is the most frequently produced series. It can be operated with wear parts for vibrocompaction as well as for Dry Bottom Feed stone columns and vibrated concrete columns. It is electrically driven.

The basic dimensions of the vibroflot and the technical data are shown below.

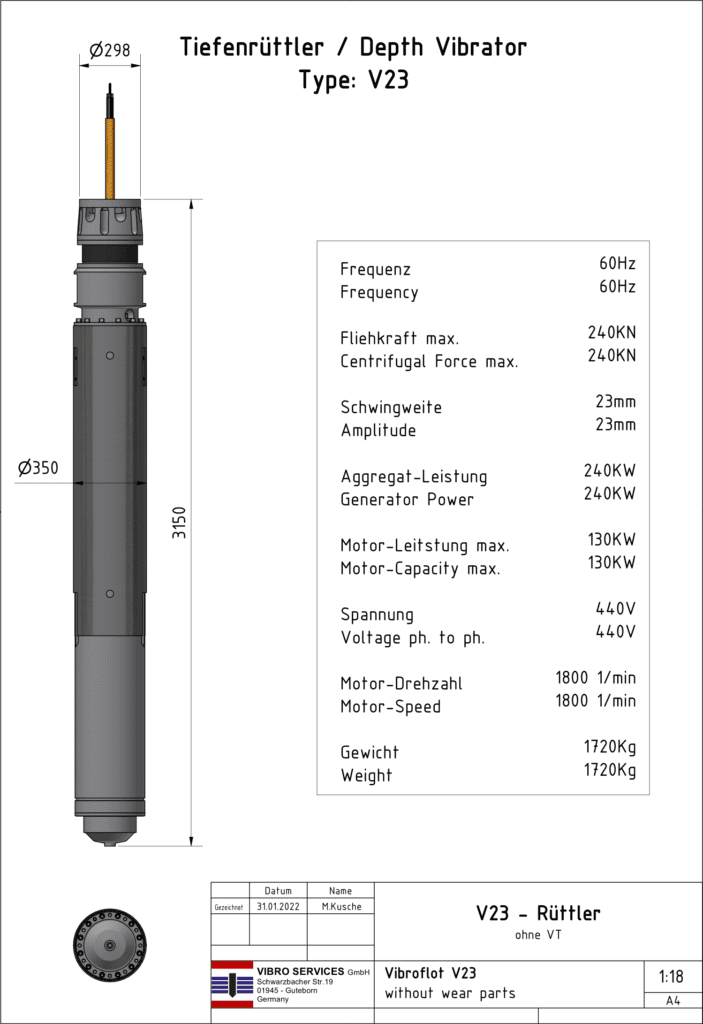

ELECTRICALLY DRIVEN

WITHOUT WEAR PARTS

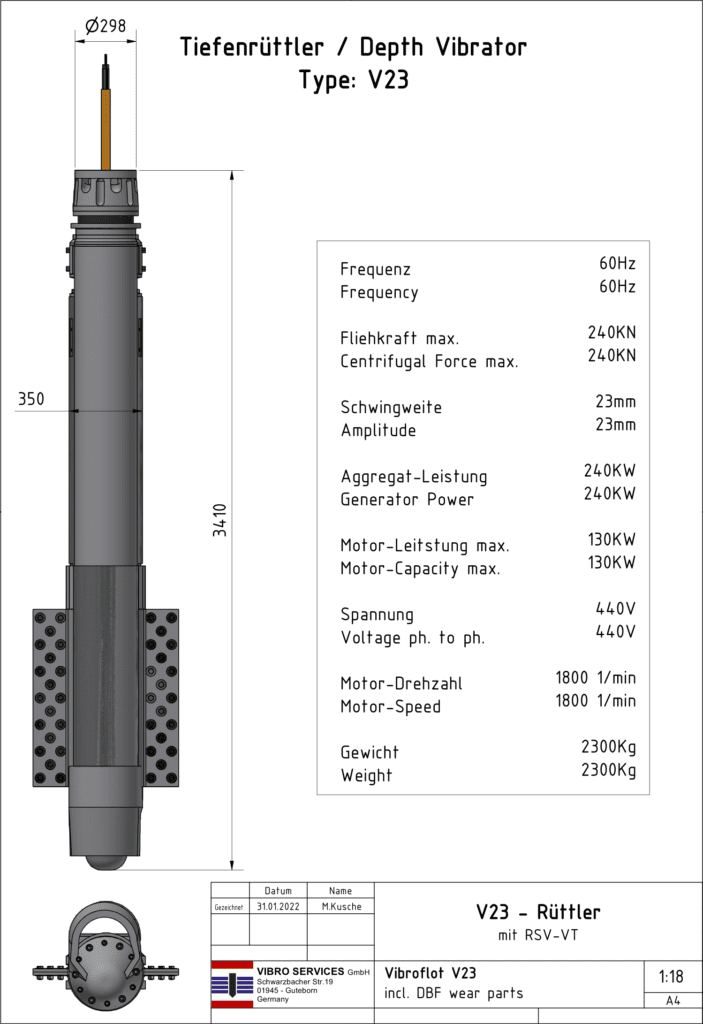

ELECTRICALLY DRIVEN

WITH DRY BOTTOM FEED WEAR PARTS

ELECTRICALLY DRIVEN

WITH VIBROCOMPACTION WEAR PARTS

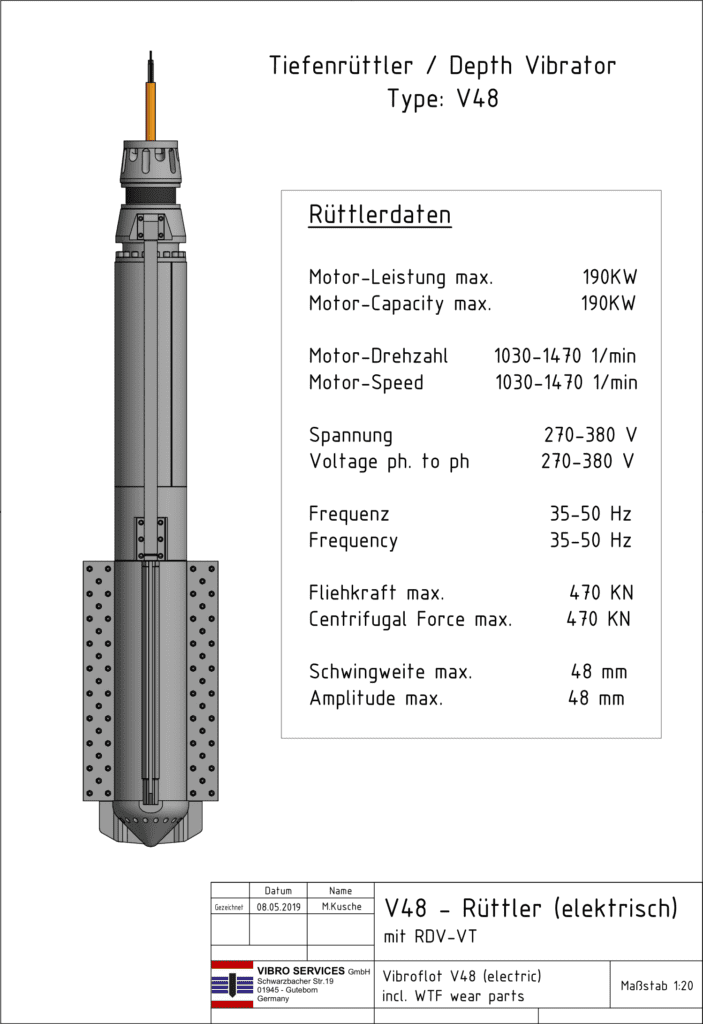

V-48

The V-48 is the most powerful in ourseries. In its size category, it is characterised by an excellent ratio between weight and impact energy.

It is electrically driven and can only be used for the vibrocompaction method.

The basic dimensions of the vibroflot and the technical data are shown below.

ELECTRICALLY DRIVEN

WITH VIBROCOMPACTION WEAR PARTS