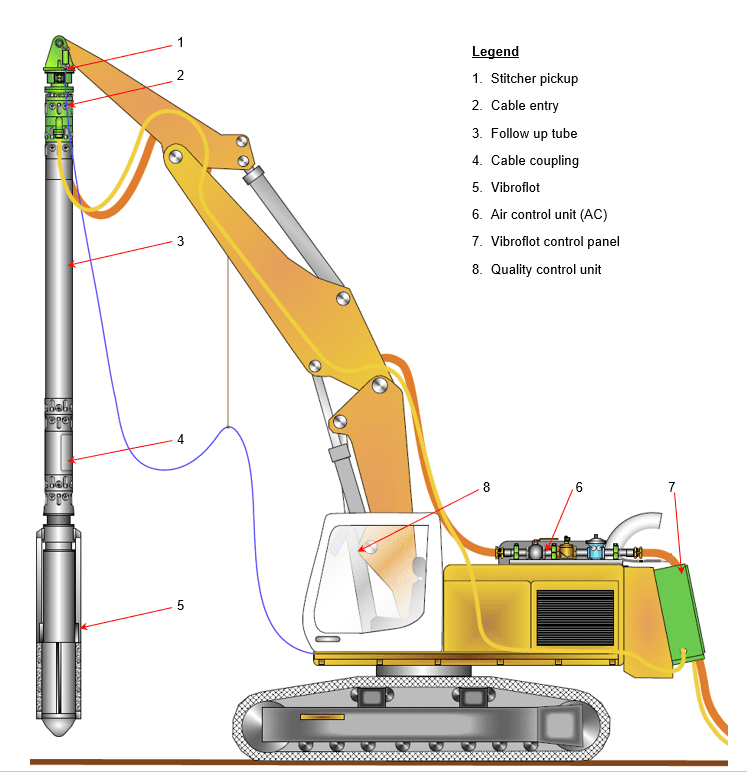

VC STITCHER

STRUCTURE OF THE PENETRATION UNIT

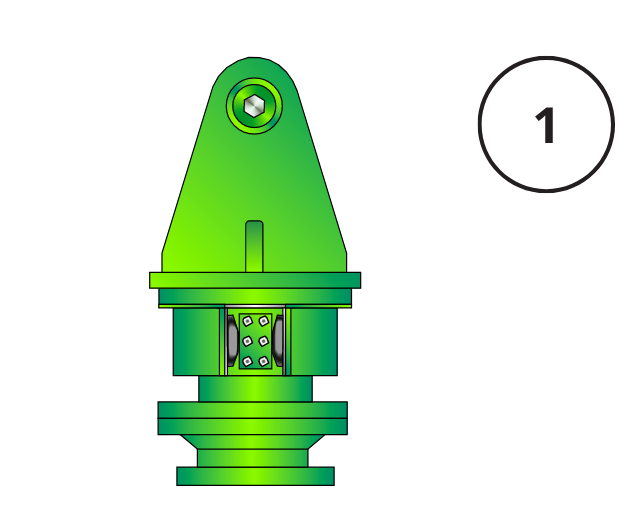

STITCHER PICKUP

The Stitcher pickup is the interface between the penetration unit and the carrier. It is a connection that allows some flexibility and vibration dampening that may be transmitted to the carrier during operations.

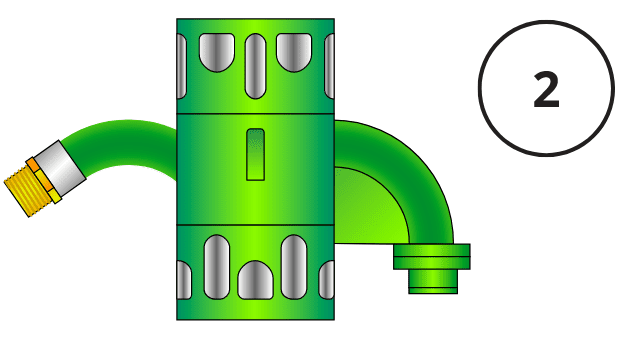

CABLE INLET

The cable inlet is a short tube section that allows the vibroflot electric cable (and air or water) to enter the penetration unit and is sealed against the penetration unit’s internal pressure.

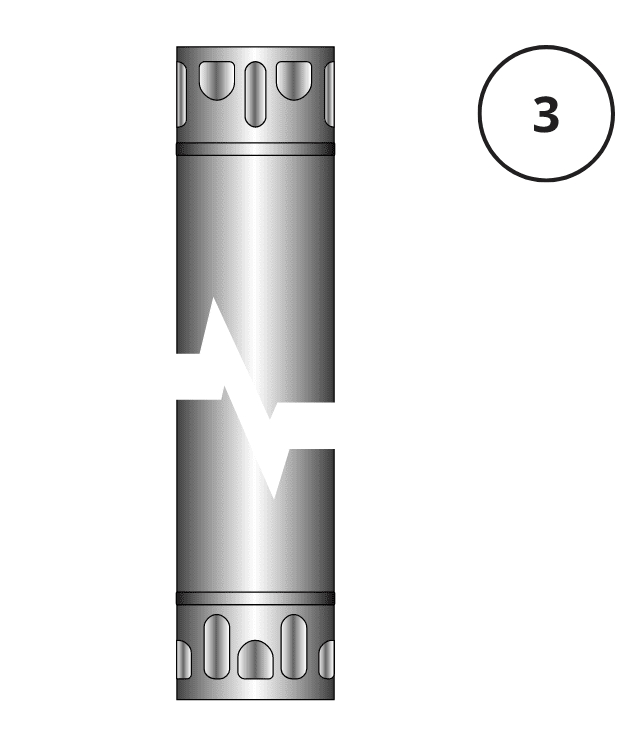

FOLLOW UP TUBE

The follow up tube is available in different lengths and thicknesses to optimize the total length and weight of the penetration unit. The penetration unit can be perfectly matched to both the carrier and working depth

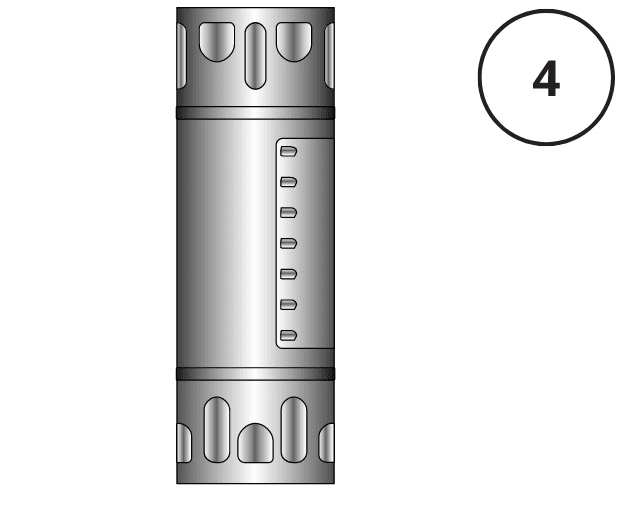

CABLE COUPLING

The cable coupling is used to connect the vibroflot electrical cable to the extension electric cable attached to the control panel. The cable coupling allows for the vibroflot to be exchanged quickly without having to remove the full length of extension cable.

VIBROFLOT

The required vibroflot is attached to the follow up tube completing the penetration unit. Vibro Services caries varied types of vibroflots that allow for individualized performance and optimised operations

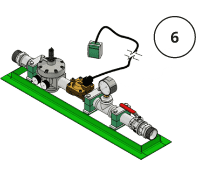

AIR CONTROL UNIT

The air control unit allows for the air system to be optimized to the ground conditions. The air pressure and air volume can be adjusted to minimize disturbance to the soil without compromising the ability for the vibroflot to penetrate to the required depth

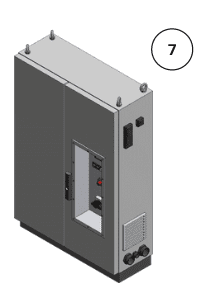

CONTROL PANEL

The control panel is used to start or stop the vibroflot as well as protect the vibroflot electric motor from operating outside pre-set values. The vibroflot temperature, voltage and amperage values are monitored by the control panel. Each vibroflot type has a control panel especially designed for its specific values.

QUALITY CONTROL

Vibro Services can supply the DIALOG quality control produced by the company Jean-Lutz. The Digital quality control records the penetration unit operating parameters. The recordable parameters include point number, date, time, vibroflot motor amperage (or hydraulic pressure), gravel volume, penetration depth, and verticality just to name a few. Data transfer is by USB stick or Bluetooth.

DBF Stitcher

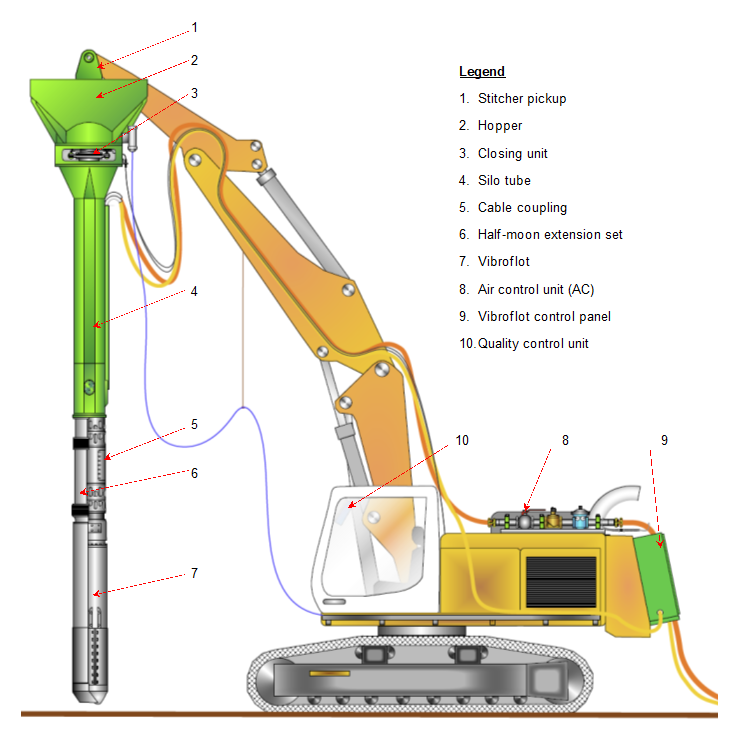

STRUCTURE OF THE PENETRATION UNIT

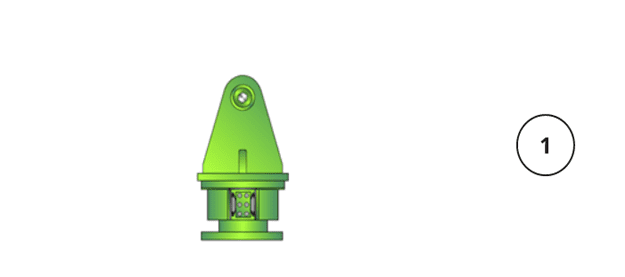

STITCHER PICKUP

The Stitcher pickup is the interface between the penetration unit and the carrier. It is a connection that allows some flexibility and vibration dampening that may be transmitted to the carrier during operations.

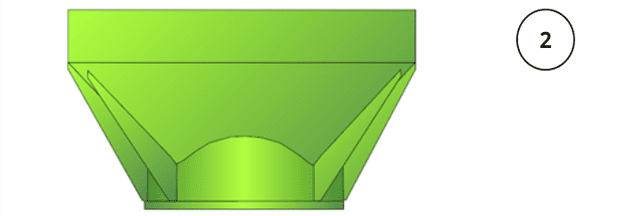

HOPPER

The hopper allows the fill material (gravel, concreate etc.) to be funnelled into the penetration unit via the closing unit

CLOSING UNIT

The closing unit opens and closes allowing the fill material into the system. When closed, the closing unit is airtight retaining the discharge air pressure.

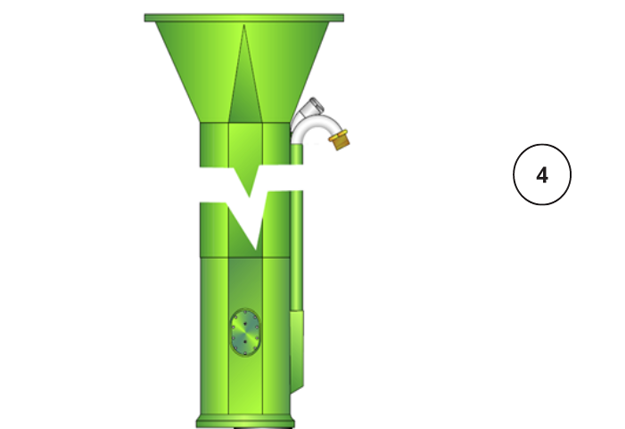

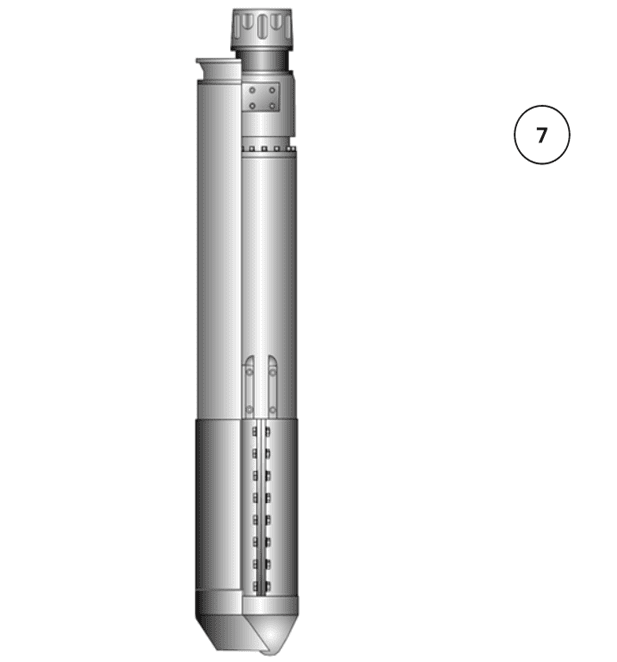

SILO TUBE

The silo tube holds a reserve of material which is used for the column construction. While the material inside the silo tube is being used, a telescopic shovel loader brings the next batch of material ready for use. The silo tube is available in different lengths to optimize the total length and weight of the penetration unit. The penetration unit can be perfectly matched to both the carrier and working depth.

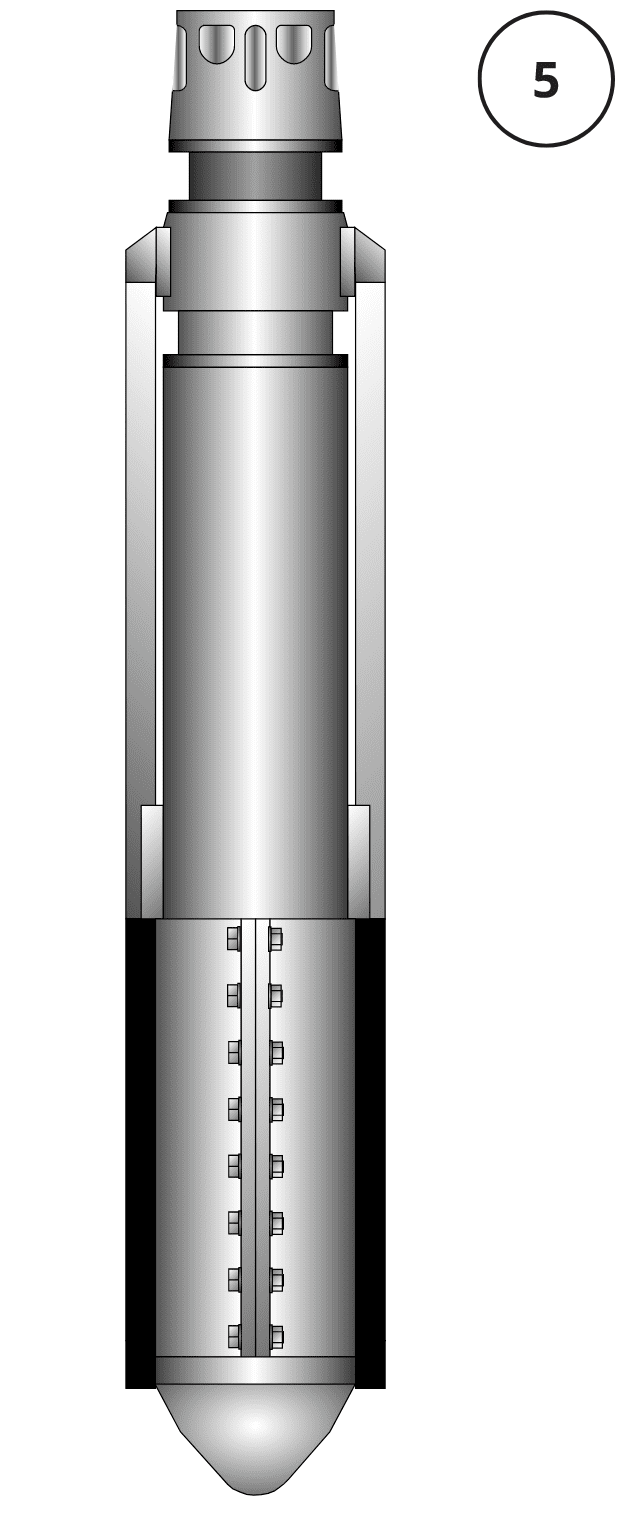

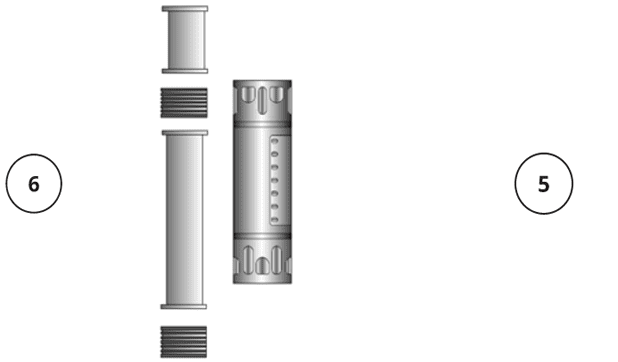

HALF-MOON EXTENSION (set) (5)

The half-moon extension set is a flexible material transfer system that allows material to be transferred from the silo tube which is static to the vibrating vibroflot without transmitting the vibration from the vibroflot into the rest of the system and carrier.

CABLE COUPLING (6)

The cable coupling is used to connect the vibroflot electrical cable to the extension electric cable attached to the control panel. The cable coupling allows for the vibroflot to be exchanged quickly without having to remove the full length of extension cable.

VIBROFLOT

The required vibroflot is attached to the base of the silo tube completing the penetration unit. Vibro Services caries varied types of vibroflots that allows for individualized performance and optimised operations

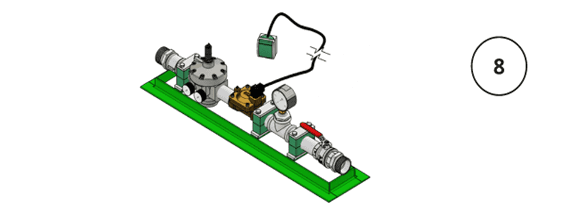

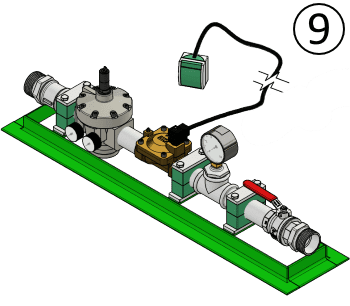

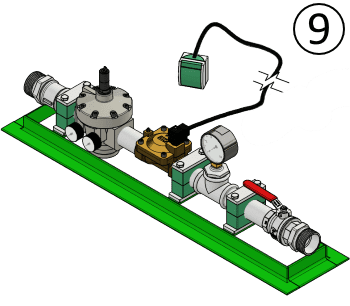

AIR CONTROL UNIT

The air control unit allows for the air system to be optimized to the ground conditions. The air pressure and air volume can be adjusted to minimize disturbance to the soil without compromising the ability for the vibroflot to penetrate to the required depth

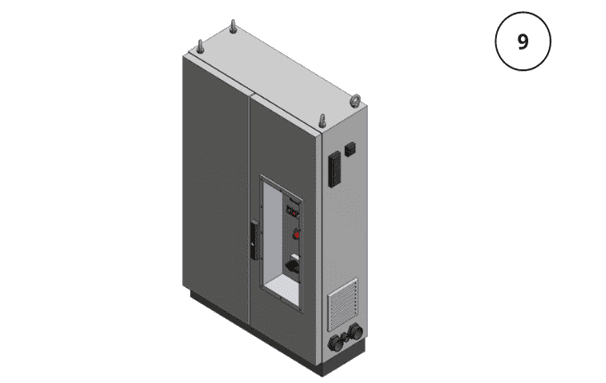

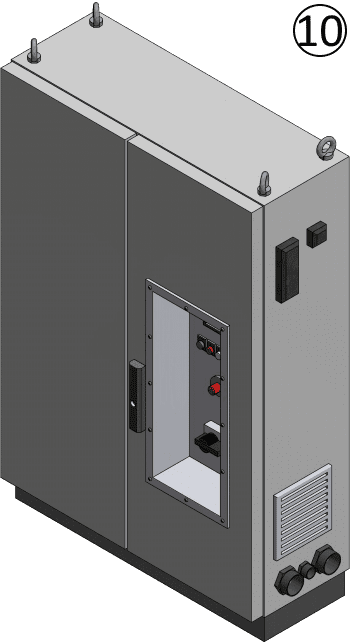

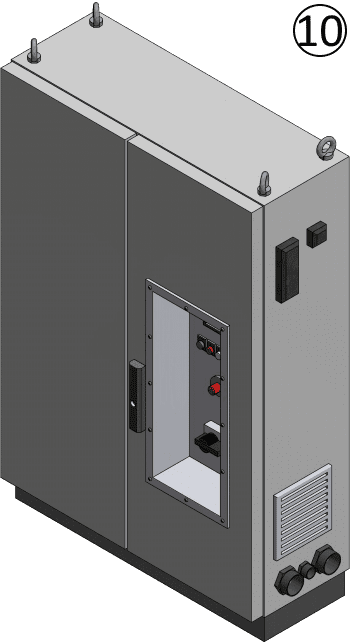

CONTROL PANEL

The control panel is used to start or stop the vibroflot as well as protect the vibroflot electric motor from operating outside pre-set values. The vibroflot temperature, voltage and amperage values are monitored by the control panel. Each vibroflot type has a control panel especially designed for its specific values.

QUALITY CONTROL

Vibro Services can supply the DIALOG quality control produced by the company Jean-Lutz. The Digital quality control records the penetration unit operating parameters. The recordable parameters include point number, date, time, vibroflot motor amperage (or hydraulic pressure), gravel volume, penetration depth, and verticality just to name a few. Data transfer is by USB stick or Bluetooth.

Vibrocompaction Free-Hanging

Components for control/regulation (located on the carrier device)

COMPRESSED AIR REGULATOR

Description will follow shortly

SWITCHBOARD

Description will follow shortly

DBF Free-Hanging

Components for control/regulation (located on the carrier device)

COMPRESSED AIR REGULATOR

Description will follow shortly

SWITCHBOARD

Description will follow shortly